Siemens and the Practice of People Centricity in CRISP Manufacturing™

The Future Factory team recently met with Siemens leaders and researchers to examine how a people-centric approach to digital learning and artificial intelligence is reshaping work across the company’s manufacturing network. Drawing on two in-depth cases, the discussion examined what it takes to turn ambitious digital initiatives into everyday practice on the shop floor.

This analysis synthesises insights from two in-depth Siemens cases: “How Siemens Empowered Workforce Reskilling and Upskilling Through Digital Learning” by Leonie Rebecca Freise, Eva Ritz, Ulrich Bretschneider, Roman Rietsche and Gunter Beitinger, and “The Culture Clash of AI Adoption in Lean Quality Management: Resolving the Tensions at Siemens Electronics Works Amberg” by Benjamin van Giffen, Gunter Beitinger, Helmuth Ludwig, Bill Schiano, Konstantin Schmidt and Jan vom Brocke. Together, these studies provide a concrete illustration of how people-centric practices can sustain performance at scale in a highly digitalised production environment.

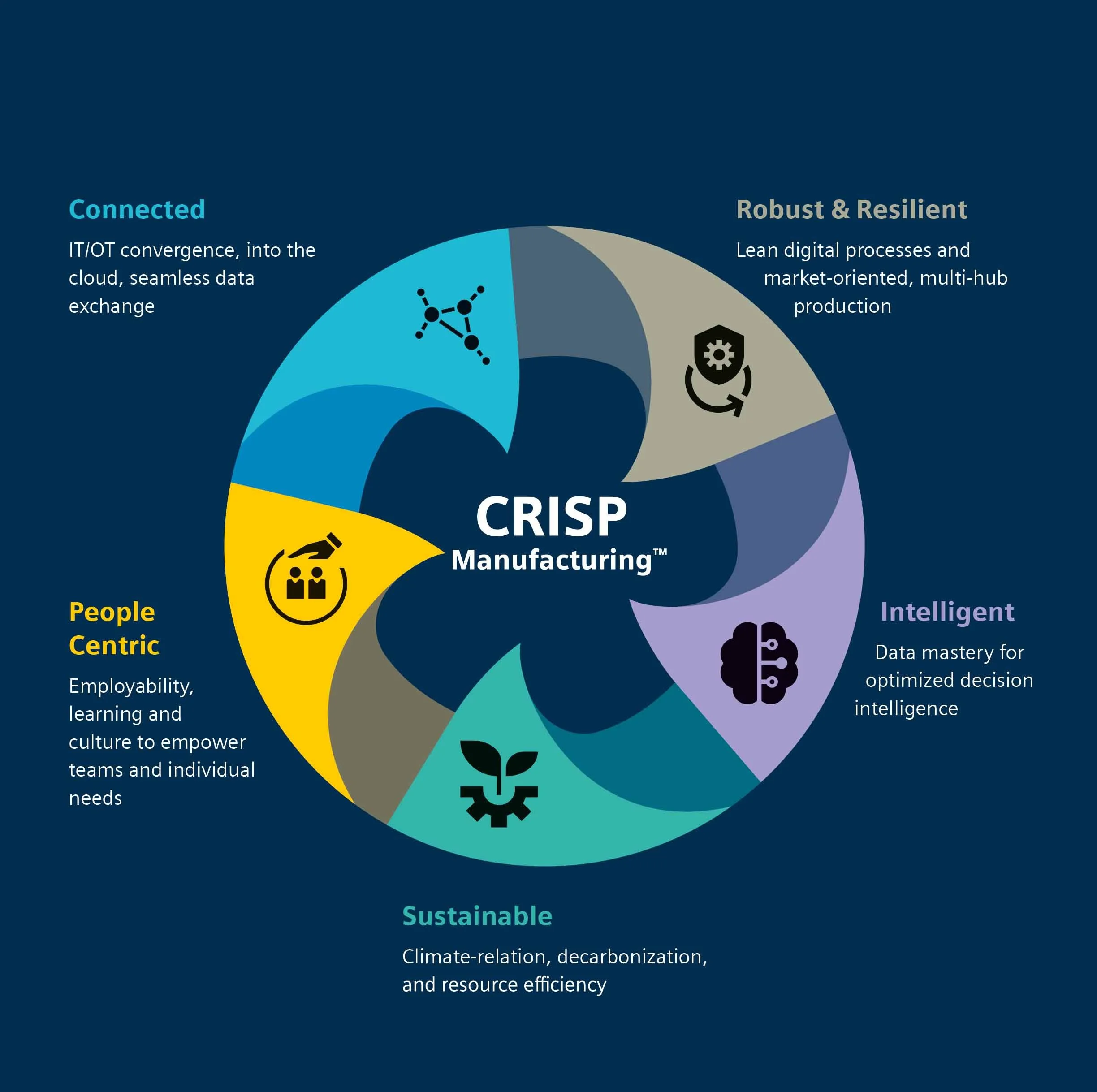

Within the CRISP Manufacturing™ framework, the P for People represents the capacity of organisations to empower their workforce as active, informed agents of transformation rather than passive recipients of technological change. Siemens provides a compelling demonstration of this principle through its twin commitment to human-centred digital learning and inclusive artificial-intelligence (AI) adoption in its production network.

At the strategic level, Siemens recognises that sustainable productivity in a highly digitalised, globally distributed manufacturing system depends less on any single technology and more on people’s ability to adapt, learn and co-evolve with technology. Confronted with the accelerating pace of digitalisation and Industry 4.0, the company built a scalable learning ecosystem rooted in human-centric design. Guided by the maxim “Making learning a habit”, Siemens invested heavily in an internal digital learning platform offering more than 130,000 courses. The platform combines data-driven personalisation with human support: mentors, peer exchanges and short “learning nuggets” enable employees to integrate study into daily work. This combination of intelligent content delivery and social support improved measured learning effectiveness by 22 per cent and strengthened retention and satisfaction across all manufacturing sites.

The underlying philosophy is that technology must serve people’s development rather than the reverse. Siemens therefore evolved its learning approach through four phases: identifying employees’ practical learning needs; understanding personality traits that shape digital learning behaviour; developing human-centric learning strategies; and aligning those strategies with organisational goals. The resulting model replaced uniform training with adaptive pathways attuned to individual preferences and roles. In this way, digitalisation became an enabler of autonomy, personal agency and professional development, which are hallmarks of People Centricity.

This people-first ethos is equally evident in Siemens’ integration of AI into quality management at Electronics Works Amberg (EWA). Here, the company confronted a classic culture clash between the exploratory nature of AI and the precision of lean production. Rather than positioning AI as an opaque expert system imposed on the shop floor, Siemens framed AI introduction as a co-creative learning process. Data scientists, engineers and shop-floor employees worked in iterative sprints to design and refine an AI model for quality prediction in printed circuit board assembly. Extensive workshops, short learning sessions entitled “What is AI?” and an on-site help desk created psychological safety and built shared understanding of what the models could and could not do. Operators were explicitly invited to challenge the system and contribute experiential insights to model design.

Through transparent dashboards, joint validation and continuous feedback loops, the AI system matured from a pilot tool into a trusted assistant. The initiative reduced x-ray testing volume by 30 per cent, avoided a €500,000 equipment investment and preserved EWA’s world-class defect rate of 11 parts per million. More importantly, it safeguarded human expertise by embedding AI within a participatory framework of training, retrospectives and knowledge management on the shop floor. Experienced operators remained central to interpreting anomalies and maintaining the interpretive bridge between data patterns and real-world process behaviour.

Across both cases, Siemens reframed technological transformation as a human-learning endeavour. The firm’s success derives from aligning digital capability with cultural readiness, cultivating trust through transparency and investing in the continuous empowerment of its workforce. Within CRISP Manufacturing™, Siemens thus exemplifies People Centricity as a dynamic balance between automation and human autonomy, where digital systems amplify, rather than replace, human intelligence.

Siemens demonstrates that resilient manufacturing in the era of AI is not built solely on code or machinery, but on an organisational culture that regards people as the decisive source of adaptability, innovation and long-term value creation. The Siemens cases suggest that the most advanced factories of the future will be those where learning, experimentation and human judgement are designed systematically into every digital solution.

Explore our Executive Masterclasses

To translate these principles into impact in your own organisation, explore The Future Factory’s executive Masterclasses on AI and data science, smart factory transformation, supply chain and operational excellence, where senior leaders work through real cases, structured frameworks and practical roadmaps for modern manufacturing.

Further reading

For a deeper dive into the CRISP Manufacturing™ framework and its application across global factory networks, see Gunter Beitinger’s book on CRISP Manufacturing™, which expands on the people centricity principles illustrated in this Siemens case.