The AI Bubble Debate, and the Practical Path to ROI in Manufacturing

Executive Insight | February 12, 2026

For investors, manufacturing leaders, and entrepreneurs, talk of a potential AI bubble is everywhere. Many remember the dot-com boom and bust in 2000 and the housing market unwind in 2008. AI is advancing quickly, and expectations can rise faster than adoption. Some organisations have also moved too quickly from pilots to large-scale change, only to find the operational reality is more demanding than the headlines implied.

Manufacturing leaders should ask a different question from investors. Does an AI bubble even matter for my company? In practice, the bubble is rarely the point, what matters is leveraging the real value of AI that exists whether the bubble grows or pops. The real priorities are understanding what AI can do and what it cannot, tracking how capability evolves along a non-linear path, avoiding common traps in implementation, and recognising where underinvestment creates material downside.

Substance Behind the AI Bubble

A bubble, if it exists, is largely a market story rather than a technology verdict. Capital can chase narratives, valuations can run ahead of reality, and some growth strategies prioritise speed over economics. When that happens, a correction is normal. Manufacturing should not confuse that market cycle with the usefulness of AI on the shop floor or across the value chain. The dot-com era is a helpful analogy because the internet delivered enduring value even while many early investments were poorly grounded. The practical question is whether AI can improve performance in the processes that matter.

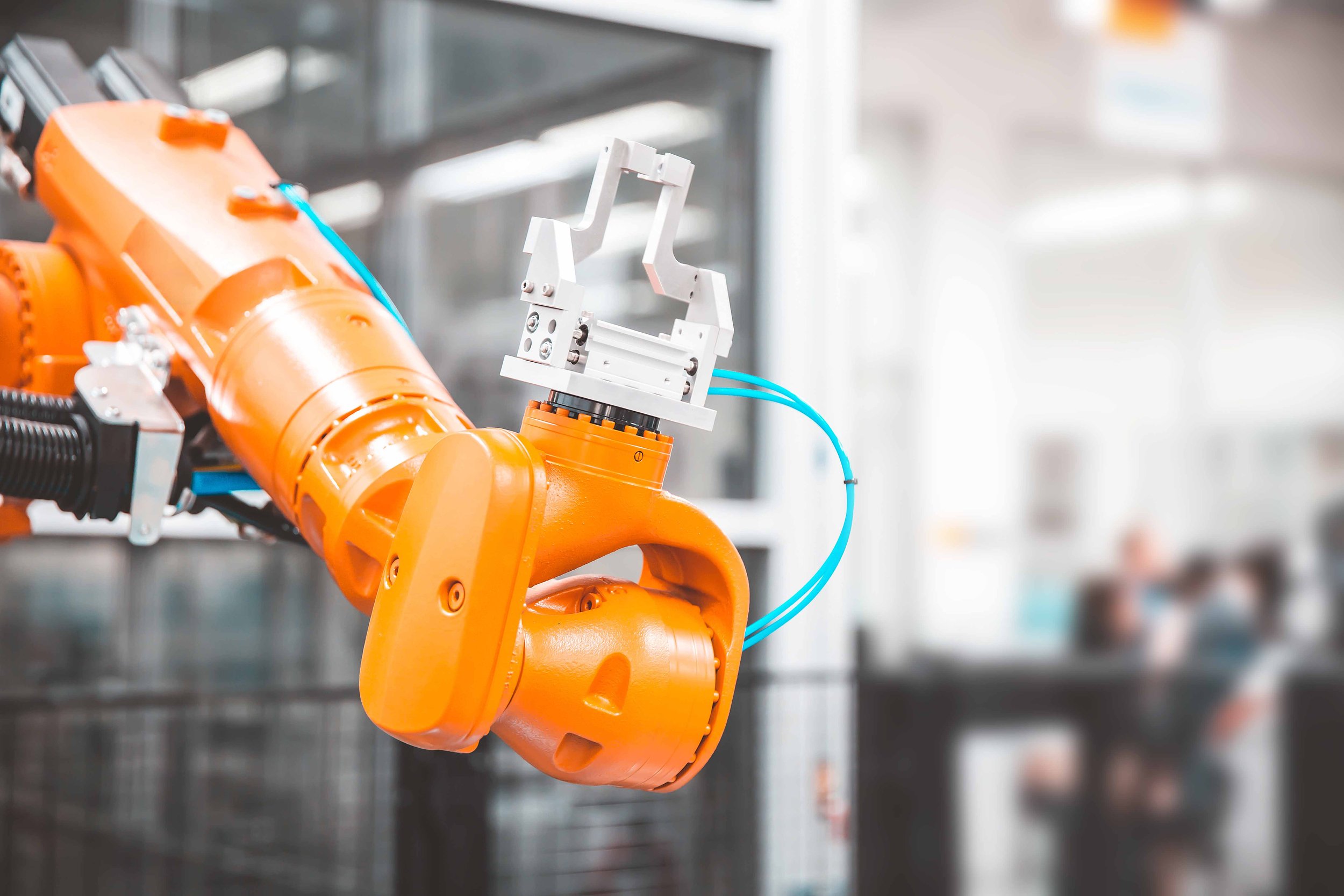

Where AI Already Delivers Value

AI is not a single technology. It is a family of methods that solve different classes of problems. In manufacturing, the highest-confidence value tends to come from use cases with clear objectives, stable conditions, and measurable outputs.

Quality inspection is a strong example. Computer vision can be effective when lighting, timing, positioning, and part presentation are controlled. Models can be tuned to prioritise caution, flagging ambiguous cases for review. That design supports human-in-the-loop execution. AI handles the high-confidence volume and routes uncertainty to experienced operators who resolve edge cases and strengthen the system over time.

Predictive maintenance and condition monitoring are similarly mature when sensors, maintenance histories, and failure modes are understood. The goal is fewer unplanned stops, better intervention timing, and improved asset availability.

Simulation and optimisation can pay off when constraints are clear. Scheduling, energy management, inventory policies, and distribution decisions often benefit from models that evaluate trade-offs quickly across large data sets. In many global manufacturers, the enabling step is unifying operational data across sites so analysis can see the system end to end. Programmes at firms such as Michelin and ABB illustrate this pattern. Disciplined data foundations make scaled AI deployment more realistic.

Making AI Programmes Work at Scale

When AI disappoints, it is often because leaders scale before the foundations are ready. A pilot can look promising in a controlled environment, then struggle in production when data drifts, operating conditions vary, or responsibility for monitoring and retraining is unclear. There are many advantages of scaling up AI within an organisation, but research is still uncovering longer term effects of embracing blanket AI tools, effects that may cause long term damage to work life balance, productivity as a whole, and the ability to focus on a single task at a time.

Another common mistake is treating automation as substitution rather than redesign. Many processes fail because information is fragmented, handoffs are unclear, and exceptions are handled inconsistently. AI can help, but the best outcomes typically come from pairing AI with human judgement. Let the model handle repeatable decisions at high confidence, and ensure experienced people handle exceptions, safety-critical calls, and novel situations.

Generative AI and Operational Reality

Generative AI has raised expectations because it feels powerful in personal use. Large language models, often shortened to LLMs, can draft, summarise, and brainstorm with impressive fluency. That experience can tempt organisations to assume similar reliability in business-critical work.

Manufacturing environments impose a higher standard. Outputs must be consistent, traceable, and safe. The data context must be correct, the logic must be explainable enough for governance, and the system must behave predictably under unusual conditions. Generative tools can still add value, but the role is different. They can accelerate documentation, support training, assist engineers with knowledge retrieval, and help teams explore options faster. They are strongest when they augment experts rather than replace them.

This is already visible in engineering and product development. Organisations such as Airbus have discussed using generative methods to accelerate parts of aerodynamics and design analysis, reducing cycle time for exploration while keeping expert review and decision-making in place.

How to Get to ROI in Manufacturing Today - A practical sequence works

The companies earning ROI tend to start with process. AI is a tool, not a strategy. If the problem is not defined, the data cannot be targeted, the success metrics cannot be agreed, and the project cannot be governed well.

First, define the process and the performance gap. Use Lean methods to link process metrics to outcomes and to make root causes visible. If an improvement can be achieved without AI, take it. That often raises baseline performance and improves data discipline, which makes later AI projects easier.

Second, invest in the data foundation. Standardise definitions, ensure capture at the right points in the value stream, and make data accessible with appropriate controls.

Third, choose use cases where the environment is controllable and the payoff is measurable. Vision inspection, anomaly detection, predictive maintenance, and constrained optimisation tend to be practical starting points.

Fourth, design for adoption. Map the human workflow and the decisions that need to be made. Build the interface so the model output is actionable, with context that supports trust. The aim is faster and more reliable decisions, not blind automation.

A useful metric here is time-to-correct-action. How quickly can the system turn data into insight, present a recommendation with context, and enable a technician or engineer to act correctly?

Next Steps for Manufacturers

Whether the wider market is in a bubble or not, manufacturers should focus on building AI capability. Invest where AI is already strong, and build the digital and operating foundations that make scaling possible. Done well, AI can improve quality, reduce downtime, shorten cycle times, and lower cost. It can also help organisations make better use of scarce expertise by routing attention to the problems that truly need human judgement. AI will keep evolving, and expectations will continue to swing. Manufacturers do not need to chase every headline. They need to build the conditions for AI to work, then scale what delivers measurable outcomes.

About the author:

Nathan Eskue is Associate Professor in the Faculty of Aerospace Engineering at TU Delft, specialising in AI, robotics, manufacturing, project/business management, and rapid iteration prototyping. He holds degrees in business information systems, marketing, operations management, an MBA, and a Master of Science in Data Science from Columbia University. Nathan has spoken at over fifty international conferences on AI, aerospace/defense, quantum, and other technical topics. He’s worked for NASA, Raytheon, Northrop Grumman, and other aerospace organisations for over twenty years, with experience in product development, project management, supply chain, manufacturing, and AI architecture.