Innovation focuses in the automotive industry

Image SEAT

The great Digital Tsunami is washing over the world’s industries, arriving to some organisations before others, but it will reach everyone in the end. In these defining times concepts like digitalisation, Smart Factory and Industry 4.0 need further clarification. At SEAT we like simplifying this terminology - not just for our clients, but also in terms of our making our processes clearer and more efficient. Digitalisation is the process of leveraging digital technologies and business models to provide new revenue streams and value opportunities, The Smart Factory is the introduction of digital technologies in manufacturing plants and Industry 4.0 is the brand to promote the concept.

In terms of digital strategy, inactivity and lack of decision-making are a recipe for obsolescence. If organisations wait for the movements of others in an attempt to copy them, the speed of change is so great that they will run out of response time. Consequently, for the automotive industry and especially for a brand like SEAT, the only option is to lead the change, define the digital future and be a true industry pioneer.

Once digitalisation is understood in the industrial context, it is time to redefine strategies. As all industries become digitalised, every department within a company will also undergo transformation. At this stage, it is advantageous to implement a business exercise and define how each department envisions the digital transformation of their function. In short, define what and how we want to be in this digital future.

Image SEAT

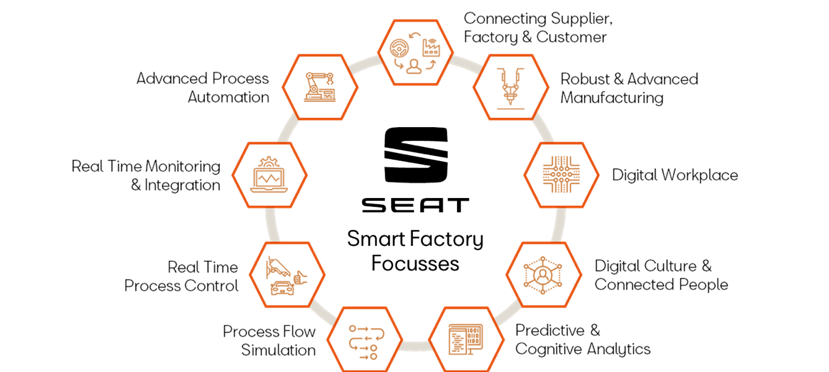

In SEAT, this very exercise was carried out in all areas of production and quality, since both have shared strategies for many years. As each of these functions established their own definitions they were amalgamated to draw a shared digital vision of production and quality. This digital vision is composed of nine digital innovation approaches, through which all innovation and technology activities are articulated:

Advanced Process Automation. The key focuses here are robots (sensitive, mobile and collaborative) drones and exoskeletons. The objective is to advance one step beyond traditional automation, taking advantage of the power of artificial intelligence to generate far more disruptive concepts such as swarm robotic or super-flexible manufacturing cells.

Process Flow Simulation. In this area, the main topics are both the simulations of every productive process and the digitalisation of all the corresponding assets and documentations. The creation of 'digital twins' enable us to build and simulate a 'parallel factory' to predict the outcome of any hypothetical situation and prepare the appropriate response.

Predictive and Cognitive Analytics. This focus is primarily concentrated on the treatment of information and the subsequent decision making. We explore big data, machine learning and all disciplines aimed at generating an artificial intelligence capable of satisfying the most ambitious digital use cases.

Digital Workplaces. This encapsulates all technologies through which people interact directly with the virtual, augmented and mixed reality world. The objective is to generate virtual tools and spaces that allow people to interact globally without requiring the use of analogue tools such as paper.

Real-Time Process Control. Using artificial vision, asset geo-location, advanced sensors and automatic identification, we capture the physical reality and convert it into a digital version. This enables real-time decision making on the production line and the channelling of data into the rest of the systems monitoring and analytical elements.

Robust and Advanced Manufacturing. Conducting research on additive manufacturing, the science of new materials and manufacturing processes. This focus aims to design the future factory and define its rules.

Image SEAT

Real-Time Monitoring and Integration. Here real-time data transmission and visualisation protocols, information processing and the development of advanced man-machine interfaces are related. Pursuing the definition of new forms of interaction with machines, visually, by voice, and other interactive methods.

Connecting Supplier, Factory and Customer. By capturing, quantifying and valuing the immense amount of data produced by the production process it can then be exchanged with other agents beyond the factory's limits to establish new use cases and revenue sources with external ecosystems. This is where we utilise the internet of things for its maximum potential.

Digital Culture and Connected People. Finally, but not least, people. Through involving people at the very heart of the process, we can study how to generate activities, tools and processes to accompany them throughout their digital journey and create a successful digital culture.

About the Author

Francisco Requena is Head of Innovation and Smart Factory at SEAT